When it comes to fluid pumping systems, NPSH, or Net Positive Suction Head, is a critical factor that design and application professionals must understand. The question at the heart of NPSH is whether the pump’s suction has enough pressure to prevent cavitation – a troublesome issue associated with noise, inefficiency, and damage to pumps. However, delving into NPSH reveals that it is more intricate than it appears at first glance. Let’s explore NPSH and its pivotal role in pump selection, especially in open systems that solely rely on atmospheric pressure.

Figure 1: Damaged impresser due to vapor bubbles formation and collapse

To grasp NPSH fully, we must first comprehend cavitation, a noisy and costly phenomenon. In open systems, if the pressure of the pumping water drops below its vapor pressure, it leads to the formation of vapor pockets – akin to pockets of steam – within the hydronic system. When the water pressure increases beyond its vapor pressure, these vapor pockets collapse, resulting in powerful implosions. The consequences of such implosions are not to be underestimated:

- Excessive noise

- Damage to pump impellers due to vapor bubble formation and collapse

- Significant deviations in the pump curve, as pumps cannot handle both liquid and vapor

- Broken pump shafts caused by the impeller colliding with alternating liquid and vapor bodies

The requirement for NPSH is not fixed; rather, it depends on several factors. Centrifugal pumps, for instance, experience an internal pressure drop between the suction and discharge points. Therefore, pump manufacturers provide NPSH data for specific flow rates. With a given pump curve, the required NPSH increases with flow. In mathematical terms, the pressure at the pump’s suction (NPSH) must be higher than the pressure at the pump suction (Ps) flange, MINUS the minimum pressure that may occur inside the pump at the impeller vane inlet (Pv):

Required NPSH = Ps – Pv

Cavitation ensues when the pressure inside the pump falls below the vapor pressure, causing vapor pockets to form and implode upon a sudden pressure rise.

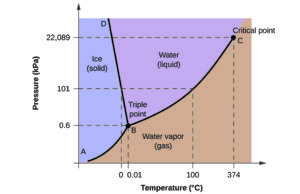

Moreover, the relationship between temperature and water vapor pressure plays a significant role. Surprisingly, even at 80°F, water can boil. At any given temperature, if the water’s pressure drops below its vapor pressure, it will transform into steam. For instance, water at 85°F has a vapor pressure of -14 PSIG. This implies that lowering the pressure on 85°F water to -14 PSIG will turn it into steam! Even water at 35°F can turn into steam under appropriate conditions.

Consequently, NPSH is a dynamic parameter. Engineers must exercise caution in open systems, selecting pumps that can operate safely within their required NPSH (NPSHR) limits.

Understanding NPSH and its role in preventing cavitation is essential for the smooth functioning of pumping systems, ensuring efficiency, and prolonging the life of the equipment. As engineers and professionals continue to refine their knowledge and apply it to pump selection and design, we can confidently overcome the challenges posed by cavitation and its detrimental effects.

By: Nash Mohammad, B.Eng